The Transfer40 pump is designed exclusively for standard diesel fuel. Do not use it with petrol, biodiesel blends, or other liquids, as this can cause damage to the pump components and void warranty coverage. Always ensure that the diesel used is clean and free from contaminants.

Perform regular inspections to ensure the pump is operating efficiently. Check for signs of wear, cracks, or leaks, and make sure the suction filter remains clean and unobstructed. Inspect the electrical connections for corrosion or loose fittings. When not in use, store the pump in a clean, dry environment to prevent rust or moisture build-up.

The Transfer40 can be connected to various tanks, provided the tank material is diesel-compatible. Using it with tanks not rated for diesel may cause leaks, degradation, or safety hazards. Always verify the tank’s specifications before installation to ensure proper chemical compatibility and performance.

The Transfer40 pump can draw diesel from a vertical suction distance of up to approximately 3 metres under ideal conditions. To maintain consistent performance, position the pump as close as possible to the fuel source and minimise the length of suction hose used.

Always operate the pump in a well-ventilated area away from open flames, sparks, or other ignition sources. Ground the pump to prevent static electricity build-up, and wear suitable protective equipment, including gloves and eye protection, when handling diesel to reduce the risk of spills or splashes.

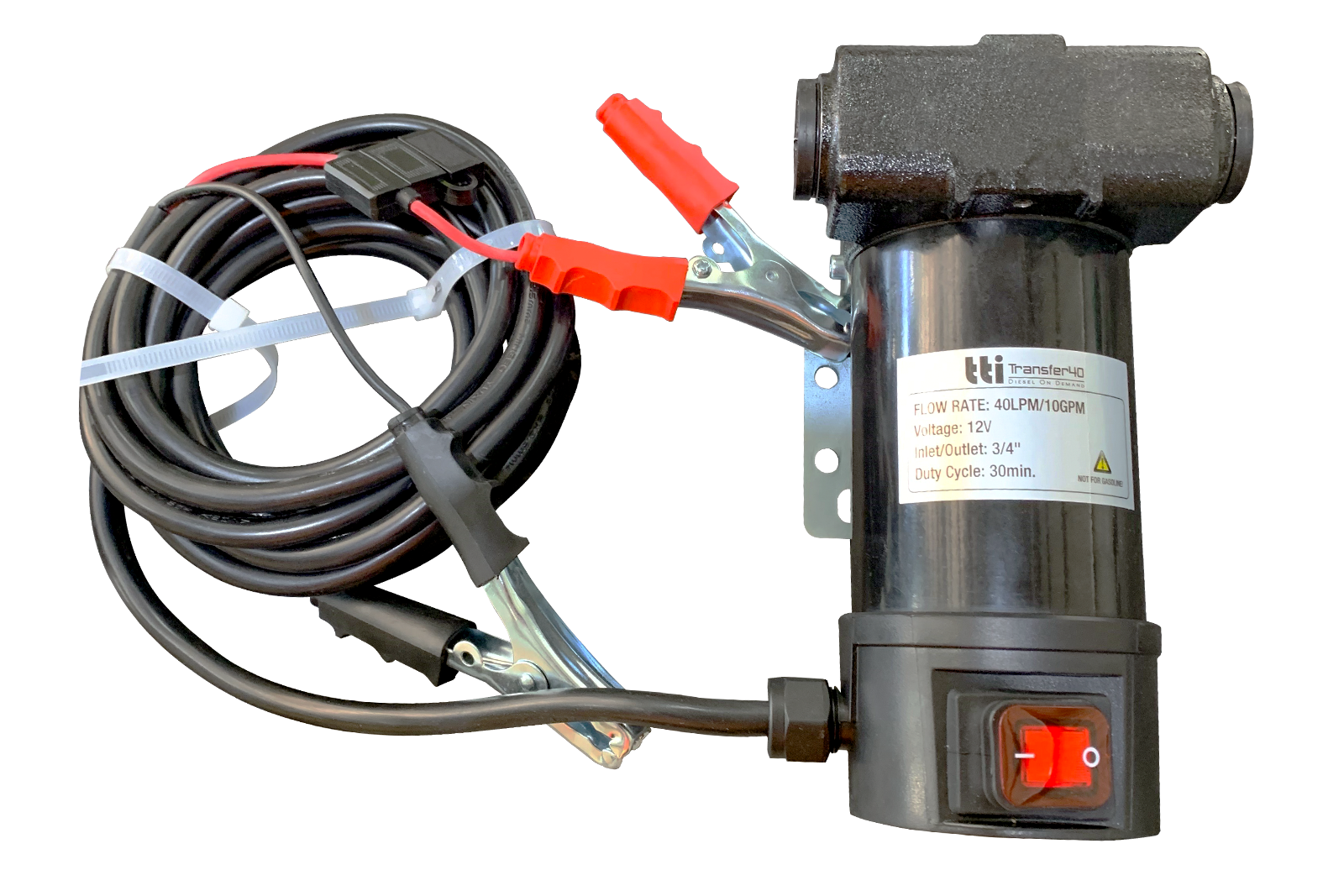

For optimal service life, limit continuous operation to around 30 minutes, followed by a short cool-down period. Continuous use beyond this may cause overheating and reduce motor lifespan. Allow adequate airflow around the pump during operation to maintain safe operating temperatures.